Cold planer

Please enable the use of cookies to view this content

The cold milling machine BM 2000/60 is designed for selective milling of lane and ground linings. Due to its size and efficiency, it is particularly suitable for repair work or complete removal of motorways and major federal roads. With a standard width of 79 in and a maximum milling depth of 14 in, large areas can be removed quickly in one work stage.

Four fully steerable track chains, operable from ground level.

Centrally positioned milling unit with machine centre of gravity above the milling drum.

Features: Maximum milling performance for an average milling depth at average speed

Application: Removing asphalt strips, creating duct trenches, road repairs, and universal surfacing work

Maximum productivity, height adjustable, broad swivel range, as well as variable belt speed for better flexibility.

Perfect weight distribution. The second water tank at the rear can be used as ballast.

With BOMAG TELEMATIC, every machine is just a mouse click away. You can retrieve location and operating data at any time and manage your fleet more efficiently. Automatic reports provide full transparency on fuel consumption, idle times, and the potential for fleet optimization. BOMAG TELEMATIC also includes real-time monitoring of pending maintenance and service history.

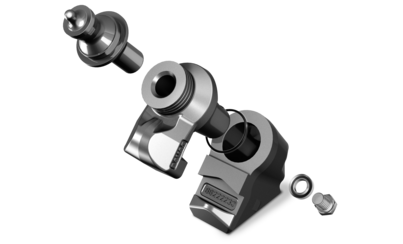

The BMS 15 holder system is slimmer than other systems. This leads to lower resistance, which reduces fuel consumption and improves the advance travel rate.

Transverse engine with mechanical direct drive and low wear angular gears.

Easy to clean, large sized cooler accessible through a wide opening door.

The adjustable control unit means maximum work comfort for the machine driver, both when sitting and standing. In addition, the entire workplace, including all control elements, is fully insulated from vibration.

The high density of the cutting tools creates a finely structured surface texture. Fine milling drums are used to increase skid resistance, prepare sites for thin pavement layers, remove road markings, and for fine milling floor coverings in halls.

The milling performance increases by 30% due to less crushing of the material. At the same time, the increased advance rate reduces fuel consumption and cutting tool wear. POWER DRUMS are used for planing particularly hard materials and for the complete removal of asphalt pavements.

Please enter your location

Electronic Parts Catalogue for Light Equipment

To the catalogueAsphalt milling is a method for removing specified layers of asphalt road pavements.

Please enable the use of cookies to view this content

BOMAG cold milling machines are designed for selective milling of lane and ground linings made up of a wide range of asphalt and concrete compounds. The different models are particularly suited for repairs or the complete removal of motorways and major federal roads, and for rural roads and inner-city work including work on roundabouts. With different working and milling depths, large areas can be removed quickly and completely in one work stage.

Our machines contain both power and performance. To deliver maximum productivity we invest heavily in perfecting our milling drums, holder systems and cutting tools.

This adds more cutting tools. Due to the high density of the cutting tools, fine milling creates a very fine surface texture and a low thickness up to 40 mm / 1.57 inch. Fine milling drums are used to increase the skid resistance of smooth road surfaces which have been “polished” by traffic. They can at the same time remove light ruts and uneven areas. In addition, these drums can be used to prepare sites for laying thin layers, to remove road markings and for fine milling of floor surfaces inside buildings.

The BMS 15 L holder system is slimmer than other systems. The effect is a lower resistance which reduces fuel consumption and improves the advance travel rate.

Cutting power per tool increases and pulverised material fragments are larger. Because of the reduced crushing effect in the milled material, energy is saved which can lead to a faster travel speed or lower fuel consumption. At the same time, the cutter has lower wear because the faster advance rate means the impact time of the cutting tools is reduced and they generate less heat. POWER DRUMS not only offer milling performance which is up to 30% higher than standard milling drums, they also provide lower wear and reduced fuel consumption. The line spacing of the cutters on the POWER DRUM is relatively wide and the surface structure created by milling is rough and coarse. POWER DRUMS are used to plane hard materials and for complete removal of asphalt pavements.

They can be used for multiple applications on a variety of milling jobs. The standard milling drum can be used for complete removal of whole road surfaces as well as for planing individual layers. The applications for standard planers extend from the removal of small sections of road (patches) to major surfacing work and road repairs, including milling duct trenches. The milled surface is an ideal base for laying new asphalt layers.

Call up the status of your vehicles from your computer or tablet. Full transparency at all times for your machine fleet with the new BOMAG TELEMATIC app for PC, iOS and Android devices.

Read more

Further data on request / All data subject to change / Illustrations may contain optional features

You can find more information regarding the CO2 emissions of all machines here.Longevity and low maintenance are two essential design principles at BOMAG implemented in the smallest details, reducing service costs and non-productive time to a minimum. With BOMAG, all components for servicing are well positioned and freely accessible. This applies to tanks, service points in the engine compartment and work on the milling drum.

Peace of mind is priority number one: This not only applies to our machines. Protect yourself from unexpected costs even after expiry of the legal warranty. With our extended warranties, you receive all-round protection for up to 60 months.

When you see BOMAG on a machine, you can expect real quality. This applies both to our original parts and our service. Opting for a BOMAG means choosing top quality every time. Original parts and service are there to protect your investment. They ensure 100% machine power and availability – and ultimately the productivity and cost-effectiveness of your company. BOMAG offers a range of service products to keep you on the road.

Learn more

Please enter your location

Electronic Parts Catalogue for Light Equipment

To the catalogue