Select your location or language

International Website

Logon em nossas áreas restritas da BOMAG

BOMAG Telematic

Não é usuário? Contate seu revendedor e obtenha acesso

Não é usuário? Contate seu revendedor e obtenha acesso

Fresadora a frio

Please enable the use of cookies to view this content

Além de ser muito fácil de operar, a máquina também se destaca com seu conceito de serviço bem pensado. 164 kW combinados com a tecnologia de corte BOMAG resultam em um desempenho incomparável.

As três velocidades variáveis de corte e fresagem são fáceis de configurar usando um interruptor no painel de controle. Isso permite a velocidade correta para cada aplicação e a melhor qualidade de superfície. Também reduz o desgaste dos rotores. Ao mesmo tempo, a velocidade de deslocamento de avanço é maximizada automaticamente – a velocidade de deslocamento de avanço pode ir até o limite.

O banco do motorista com suspensão pode ser ajustado lateralmente em até 120 mm. A partir da posição lateral, o operador da máquina tem uma visão particularmente boa sobre a área de trabalho.

Além disso, a fresadora a frio é equipada com LEDs de alto brilho. As áreas de trabalho que normalmente são escuras, serão bem iluminadas, deixa de haver problemas de visibilidades durante os trabalhos noturnos.

As quatro tampas de serviço abrem amplamente, simplificando o acesso a todos os pontos de manutenção. Os trabalhos de manutenção podem ser realizados facilmente em pé, a partir do chão.

Uma mangueira opcional, com carretel, facilita os trabalhos de limpeza diária. A limpeza prolonga a vida útil de uma fresadora, a sujeira permanece no canteiro de obras e não é transportada para o reboque ou depósito.

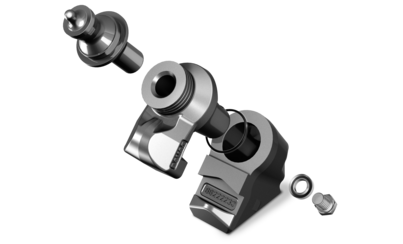

A geometria aperfeiçoada do cilindro de fresagem, em combinação com o sistema de suporte de troca BMS 15 L, exclusivo da BOMAG, garante um desempenho de fresagem excepcionalmente elevado, baixas vibrações e desgaste reduzido.

Os porta-ferramentas têm um design particularmente compacto. Esta característica permite uma economia de combustível de até 20%.

Um controlador de alta precisão, que regula a profundidade de fresagem faz parte do equipamento padrão.

A profundidade e a inclinação de fresagem são exibidas em uma tela durável e robusta. Ela está posicionada de maneira otimizada no campo de visão do operador.

A correia transportadora pode ser recolhida para facilitar o transporte. Além disso, a correia transportadora tem altura regulável em até 4.560 mm e pode ser girada em 25 graus, em ambos os lados. Esta característica facilita o carregamento do caminhão.

A altura e o raio de giro podem ser ajustados de forma rápida e facilitada com um joystick.

Graças ao conceito de refrigeração inteligente, o operador não precisa estar exposto ao ar quente da exaustão.

Em contraste com outras máquinas, o ar quente é aspirado e depois soprado para a frente.

Todos os pontos de serviço e de manutenção são facilmente acessíveis e ergonômicos. A manutenção periódica da máquina é rápida e fácil.

O parafuso do sistema de suporte deve ser apertado com um torque de apenas 100 Nm. Em comparação com os demais sistemas disponíveis no mercado, o tempo necessário para a troca completa do suporte cai pela metade.

Os sensores facilitam muito o trabalho e tornam todo o processo de fresagem mais rápido e fácil.

Com o sensor de inclinação transversal disponível opcionalmente, a inclinação transversal da estrada já pode ser definida durante a fresagem.

A potência do motor de 164 KW permite que a fresadora seja uma das mais potentes de sua classe.

O motor impressiona com um consumo de combustível surpreendentemente baixo. Este é outro fator decisivo para a economia nos custos operacionais.

O operador da máquina tem liberdade de escolha: Ele pode trabalhar em pé ou sentado.

O grande telhado de proteção contra intempéries oferece uma excelente proteção e pode ser facilmente ajustado em sua altura.

Com um raio de fresagem de apenas 380 mm, um dos mais pequenos desta classe, esta fresadora é particularmente adequada para uso em rotatórias e curvas apertadas.

O design otimizado da frente da máquina garante ao operador uma boa visibilidade geral. Isso permite que ele manobre a fresadora com facilidade e segurança.

O operador da máquina pode escolher entre três diferentes velocidades de fresagem. Estas podem ser facilmente selecionadas através de um interruptor rotativo.

O avanço é maximizado automaticamente dependendo da velocidade de fresagem e pode ir até o limite de carga. Desta forma, o desempenho do motor é utilizado de forma otimizada e, ao mesmo tempo, nenhum componente é sobrecarregado.

Por favor, introduza sua localização

Catálogo eletrônico de peças

AbertoAs fresadoras a frio BOMAG são ideais para remoção de faixas de asfalto, escavação de valas, reparos de estradas, limpeza e trabalhos de remendo.

Please enable the use of cookies to view this content

Eles têm uma vantagem competitiva com sua excelente manobrabilidade e excelente desempenho de fresamento. Com especificações diferentes, são particularmente adequados para fresamento seletivo ou remoção completa de uma ampla gama de compostos de asfalto e concreto.

As fresadoras a frio BOMAG são eficientes e potentes em praticamente qualquer cenário de canteiro de obras. A excelente tecnologia de fresagem da BOMAG, com tambores de fresagem especiais e profundidades de trabalho e fresagem ajustáveis, permite que grandes áreas sejam removidas de forma rápida e completa em uma única operação. Seja trabalhando em estradas rurais, ruas urbanas, rotatórias ou fresando seletivamente asfalto ou concreto, o trabalho do operador é sempre intuitivo.

Nossas máquinas possuem ambos: potência e desempenho. Para proporcionar a máxima produtividade, investimos intensivamente em aperfeiçoar nossos cilindros de fresagem, sistemas de suporte e ferramentas de corte.

São adicionadas mais ferramentas de corte. Devido à elevada densidade das ferramentas de corte, a fresagem fina cria uma textura de superfície muito fina e uma baixa espessura de até 40 mm / 1,57 polegadas. São usados tambores de fresagem fina para aumentar a resistência à derrapagem de superfícies de estrada lisas que foram “polidas” pelo tráfego. Esses podem, ao mesmo tempo, eliminar sulcos ligeiros e áreas irregulares. Adicionalmente, esses tambores podem ser usados para preparar terrenos para a aplicação de camadas finas, para a retirada de marcações de estradas e para a fresagem fina de superfícies de pisos dentro de edifícios.

O sistema de suporte BMS 15 L é mais estreito do que outros sistemas. O efeito consiste em uma menor resistência, que reduz o consumo de combustível e melhora a taxa de deslocação de avanço.

A potência de corte por ferramenta aumenta e os fragmentos de material pulverizados são maiores. Devido ao efeito de trituração reduzido no material fresado, a energia é poupada, o que pode levar a uma velocidade de deslocação mais rápida ou a um consumo de combustível mais baixo. Ao mesmo tempo, o cortador sofre menos desgaste, pois a taxa de avanço mais rápida significa que o tempo de impacto das ferramentas de corte é reduzido e essas geram menos calor. Os TAMBORES POTENTES não oferecem somente desempenho de fresagem, que é até 30% maior do que os tambores de fresagem padrão, como também proporcionam menor desgaste e consumo de combustível reduzido. O espaçamento linear dos cortadores no TAMBOR POTENTE é relativamente amplo e a estrutura de superfície criada pela fresagem é áspera e grossa. Os TAMBORES POTENTES são usados para fresar materiais duros e para a retirada completa de pavimentos de asfalto.

Podem ser usados para múltiplas aplicações em uma variedade de trabalhos de fresagem. O tambor de fresagem padrão pode ser usado para a retirada total de superfícies de estrada completas, bem como para a fresagem de camadas individuais. As aplicações para fresadoras padrão vão desde a retirada de pequenas seções de estrada (remendos) a grandes trabalhos de revestimento e reparos de estradas, incluindo a fresagem de valas de ductos. A superfície fresada é uma base ideal para assentar novas camadas de asfalto.

Saiba a qualquer momento onde suas máquinas estão, como elas estão sendo usadas e quando será a próxima etapa de serviço.

Ler mais

Dados adicionais a pedido / Todos os dados estão sujeitos a alterações / As ilustrações poderão conter características opcionais

Informações sobre as emissões de CO2 medidas, de todas as máquinas, podem ser consultadas aqui.A longevidade e pouca manutenção são dois princípios de design essenciais na BOMAG, que se encontram implementados nos mais pequenos detalhes, reduzindo custos de serviço e minimizando o tempo não produtivo. Com a BOMAG, todos os componentes para o serviço estão bem posicionados e são facilmente acessíveis. Isso se aplica aos tanques, pontos de serviço no compartimento do motor e trabalhos no cilindro de fresagem.

A tranquilidade é a prioridade número um: isso não se aplica somente às nossas máquinas. Proteja-se de custos inesperados, mesmo após expiração da garantia legal. Com nossas garantias prolongadas, você receberá proteção integral de até 60 meses.

Quando vir BOMAG em uma máquina, você pode esperar a verdadeira qualidade. Isso se aplica às nossas peças originais, bem como ao nosso serviço. Optar por uma BOMAG significa escolher a melhor qualidade, sempre. As peças originais e o serviço existem para proteger seu investimento. Eles garantem 100 % de disponibilidade e potência da máquina — e, por fim, a produtividade e rentabilidade de sua empresa. A BOMAG oferece uma vasta linha de serviços para manter você na estrada.

Saber mais

Por favor, introduza sua localização

Catálogo eletrônico de peças

Aberto