HYBRID

The hydraulic hybrid drive allows part of the movement energy to be recovered (recuperated) during braking.

In addition to the conventional diesel combustion engine, BOMAG HYBRID rollers come with three additional components in the drive train: a pump, pressure accumulator and reservoir.

The braking energy is initially stored hydraulically and later released again flexibly. The hydraulic hybrid drive supports the conventional drive, and the BOMAG roller saves fuel.

Please enter your location

Electronic Parts Catalogue for Light Equipment

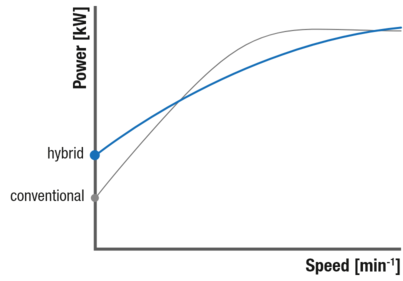

To the catalogueA hydraulic hybrid drive makes sense wherever braking and acceleration are frequent. And this is always the case when using a tandem roller on an asphalt construction site. Because a conventional engine doesn't work in the optimal range of efficiency when starting up and during vibration initiation. A hydraulic hybrid drive can support it perfectly and efficiently here.

A pressure accumulator is installed as an intermediate energy store. This is filled with gas and oil. The simple technology ensures the hydraulic hybrid is robust and easy to maintain.

A BOMAG HYBRID tandem roller is, of course, also equipped with a combustion engine. This provides the required basic power or the necessary torque.

With conventional braking, kinetic energy is dissipated in the form of heat. However, the system used by BOMAG converts this kinetic energy into hydraulic energy that can still be utilised. When braking, oil is pumped from the low-pressure tank into a pressure accumulator. The inflowing oil compresses the gas in the accumulator. The energy thus stored can be flexibly released as needed.

When load peaks occur, the pressure accumulator opens. Escaping oil drives an auxiliary hydraulic motor (hydrostatic piston engine). The result - a power boost! BOMAG is one of the few construction machinery manufacturers to have perfected and brought this system to series production readiness. With one clear objective: BOMAG construction machinery must be efficient and save fuel.

In addition to starting up, another peak load in tandem rolling is vibration initiation. Here, too, the extra energy required can be supplied by the hydraulic accumulator.

The hydraulic hybrid is combined with another groundbreaking technology – ASPHALT MANAGER. The ASPHALT MANAGER assistance system controls the amplitude infinitely variably. The result: only the power that is really necessary for vibration start-up and optimum compaction is ever used. The amplitude continuously adapts to the compaction already achieved. This also helps the construction machine save fuel.

Consumption and emissions are substantially reduced compared to a conventional drive roller: For instance, in the case of BOMAG's BW 174 AP-5 roller, the hydraulic hybrid drive can save up to 20% on fuel costs.

Our construction machines with hybrid technology use braking energy. With each change of direction, it is stored and released again when starting up.

Every job is different: Even for experienced users, every construction site poses a new challenge. Our experts are happy to advise you on the right machine and the optimum technology so that your project comes to a successful conclusion. Arrange for a consultation now.

Please enter your location

Electronic Parts Catalogue for Light Equipment

To the catalogue